Service Specials

Full Synthetic Oil Change

(Retail $105.00)

Wild Card

TIRE ROTATION

Rotate Your Tires Every 5,000 Miles For Optimal Wear

WINTERIZATION SPECIAL

Purchase Retail Oil Change

Tire Rotation, Wiper Fluid and Brake Check

BATTERY CHARGING SYSTEM TEST!

+ $10 OFF REPLACEMENT BATTERY (If Needed)

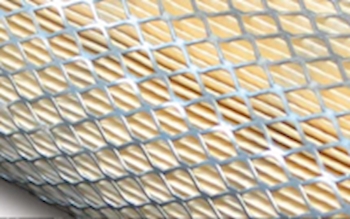

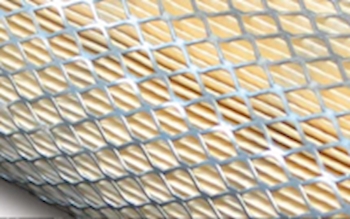

Cabin Air Filter

Keep dust, pollen ,and pollutants out of your passenger cabin with a new cabin filter. Blocks dust, Pollen, mold spores and other pollutants. HEPA Filter Technology

CABIN & AIR COMBO

Keep Your Vehicle Running & Smelling Good! Prolonging your engine's life, the air filter is designed to trap damaging dirt and debris that can damage internal engine parts such as the cylinders and pistons. The primary purpose of the cabin air filter is to filter all of the air that comes through the car's HVAC system to prevent pollutants, such as dust, pollen, smoke and mold spores, from entering.

Read More

4 Wheel Alignment

Alignments are crucial to ensuring that you get the longest life out of your tires.

Replacement Bundle

Front Wiper Blades

(Retail $75.00)

Top Engine Cleaning

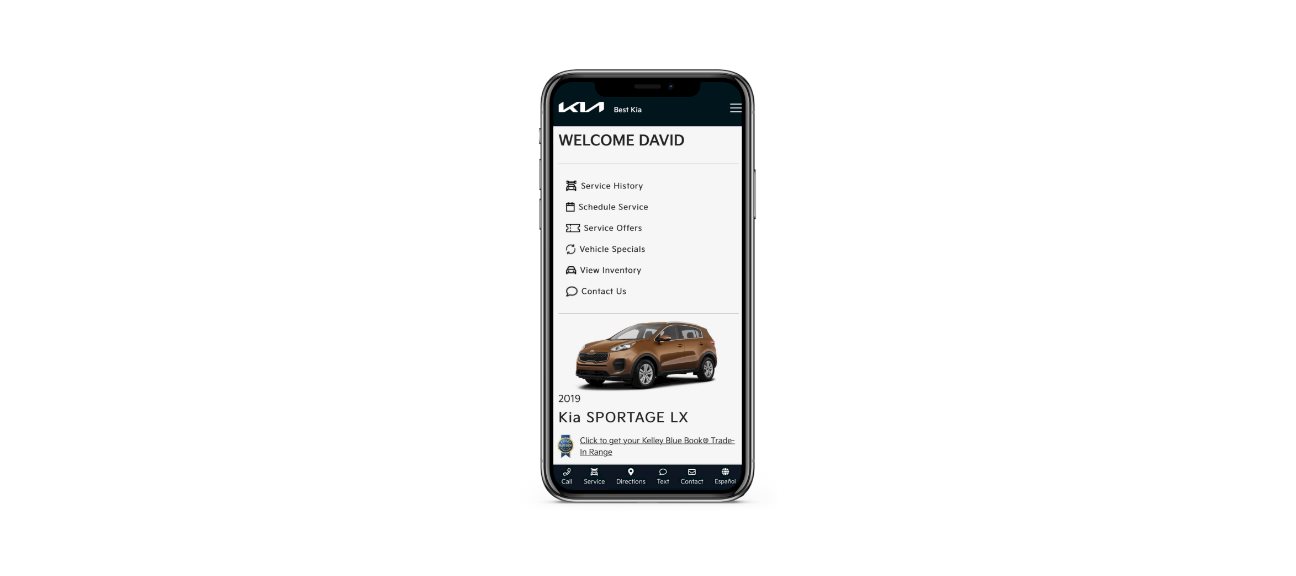

Welcome to Kia of Billings!

Proudly serving drivers from Columbus, MT, to Lockwood, MT, we offer a wide variety of outstanding automotive resources. Our inventory consists of new Kia models and high-quality pre-owned models. We have an excellent finance department in addition to a professional service center for all your auto maintenance and repair needs.

Dive into an Expansive Selection of New and Used Cars

Kia offers a wide range of sedans and SUVs, with numerous hybrid and electric models available in the lineup. You will discover a diverse selection of new and pre-owned cars at Billings of Kia. Discover the Kia Niro, Kia Sportage or EV6 in our new inventory or drive off with a like-new Kia Soul from our used inventory.

You can find models like the Kia Sportage Hybrid, the Kia Telluride, and more at our dealership. Whether you choose a brand-new or like-new model, you will get a vehicle of outstanding quality at Kia of Billings.

Explore Financing Options

The finance department at Kia of Billings offers excellent leasing and auto financing plans. You can get pre-approved by using our convenient and secure online finance application. Our finance center will work hard to ensure you get a deal and financing plan that fits your lifestyle.

Expert Service and Genuine Kia Parts

Get professional maintenance and repair services at Kia of Billings. Our service center offers various services, from oil changes to engine repairs. Our expertly trained technicians will make sure your vehicle performs to the best of its ability through routine maintenance.

If your Kia model needs a part replaced, we carry genuine Kia parts. Keep an eye out for available service specials to save on services like brake repairs, tire rotations, and more at Kia of Billings.

Visit or Contact Kia of Billings Today

Our dealership is easily accessible to drivers around Billings, MT, Laurel, MT, and nearby communities. You can contact us or swing by for a visit to explore our vast range of automotive resources. We can happily and easily answer any questions you may have about our vehicles, financing options, service center, and parts department. Visit us or contact Kia of Billings and let us know how we can best serve you.